Stonerockr™ V2 F6 Pro LCG Offset Wheels

Key Features

- 100% performance-driven design by Pierre Silva

- All-new super strong bead mounting

- Insane clearance for portal covers and knuckle weights

- Ultra light structural design

- Latest high-tech materials and 3D printing technology

- Improved X-Ventz™ System

- Extended color range for both 1.9″ and 2.2″ sizes

- Amazing 6-size offset for perfect track-width

- 100% legal to all major rulesets

- All-made in Europe

100% Performance-Driven Design

The design and tech concept of the Stonerockr™ V2 F6 Pro LCG Offset Wheel System was personally created by PROCRAWLER® founder Pierre Silva. The Stonerockr™ V2 F6 Pro was Pierre’s debut project as a designer.

Thank the sophisticated solutions Pierre took the Stonerockr™ V2 F6 Pro LCG Offset Wheels to a whole new level when it comes to performance, durability, structural and aesthetic design.

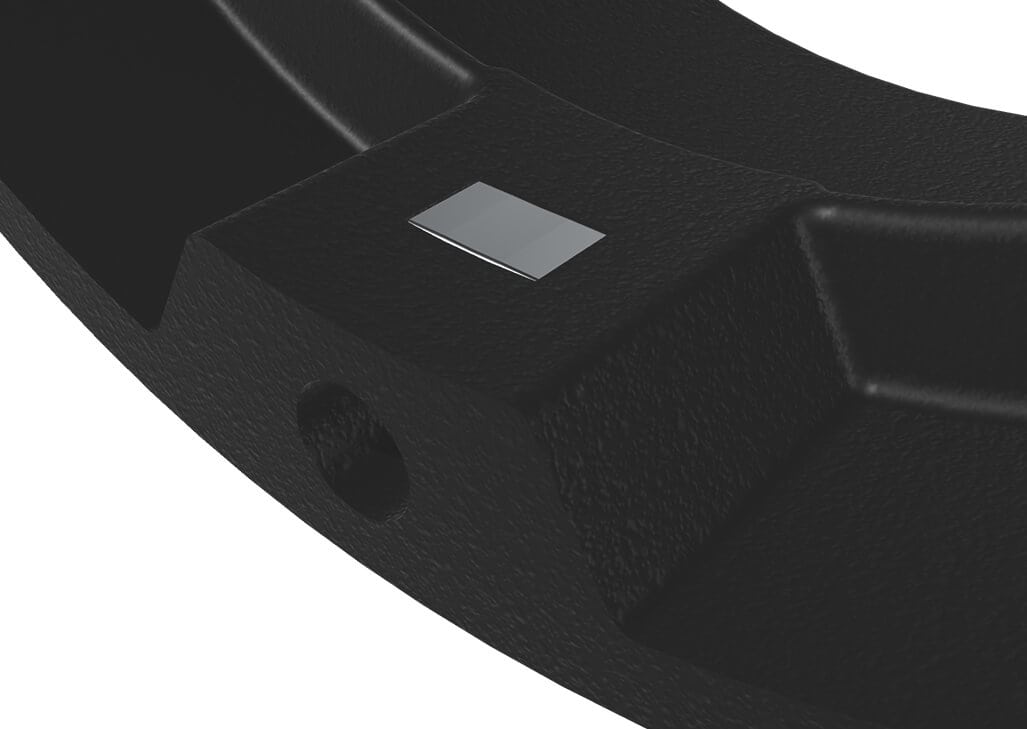

All-New Super Strong Bead Mounting

Formerly the bead screws might be ripped off by heavy duty use due to the powder based PA12 material so with the Stonerockr™ V2 F6 Pro LCG Offset Wheel System we completely changed the material and the way the bead screws are mounted to the inner ring.

The Stonerockr™ V2 F6 Pro bead screws are mounted through an integrated square nut first then they cut their own threads into the ultra homogeneous high-tech engineering resin inner ring. No ripped off screws, only strong but ultra light wheel structure.

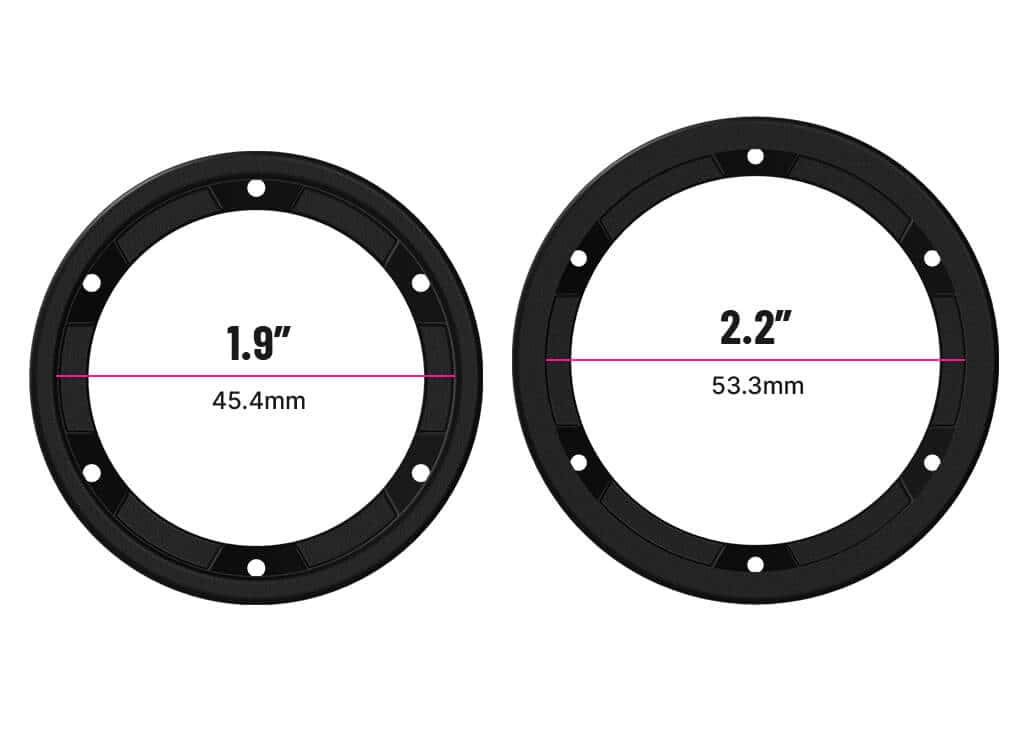

Insane Clearance For Portal Covers & Knuckle Weights

Maxed out clearance for portal covers and knuckle weights was a key goal at the product definition of the Stonerockr™ V2 F6 Pro LCG Offset Wheel System. With smart tweaks and heavy hours of thinktanks we were able to increase the original clearance in both the 1.9″ and the 2.2″ wheels.

| Wheel Size | Clearance Diameter |

|---|---|

| Stonerockr™ V2 F6 Pro 1.9" | 45.4mm |

| Stonerockr™ V2 F6 Pro 2.2" | 53.3mm |

Ultra Light Structural Design

Rotating weight is a bad weight. High rotating weight burdens the drive chain totally unnecessarily and useless: the motor loses explosiveness and reaction time while the parts of the drive chain can easily break.

| Wheel Size | Net Weight |

|---|---|

| Stonerockr™ V2 F6 Pro 1.9" | 26g/wheel |

| Stonerockr™ V2 F6 Pro 2.2" | 30g/wheel |

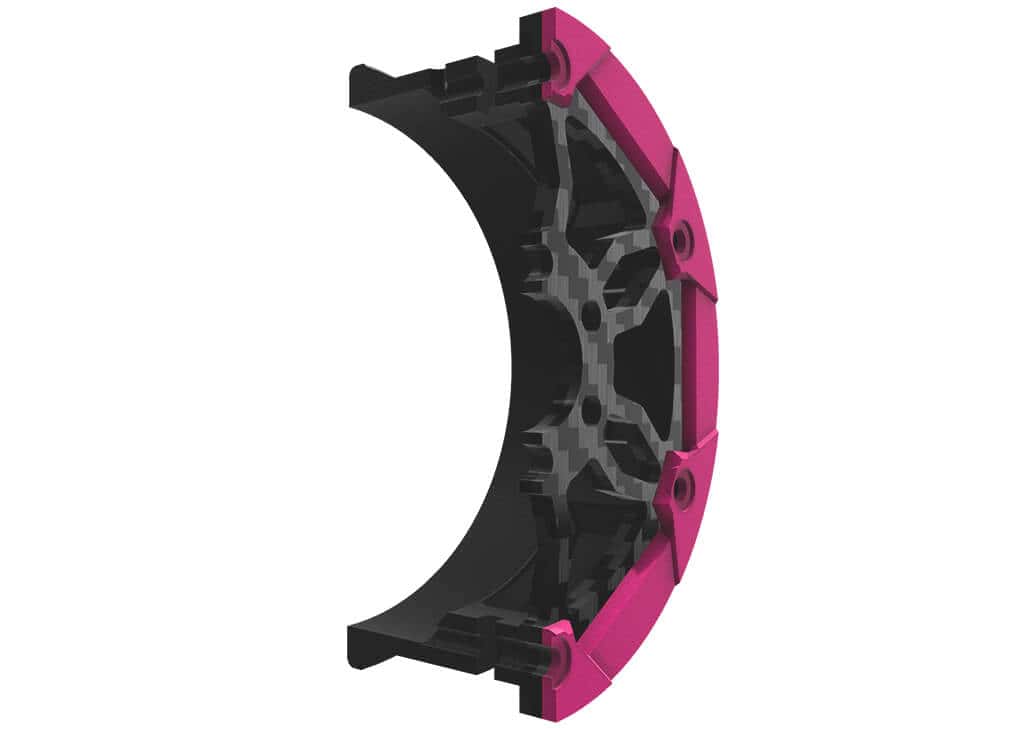

Latest High-Tech Materials & 3D Printing Technology

As we are committed to the ultimate LCG performance while keeping it durable we significantly changed both the materials and the 3D printing technology for the Stonerockr™ V2 F6 Pro LCG Offset Wheels.

Inner, bead and front rings are 3D printed of high-tech engineering resin with MSLA (Masked Stereolithography) 3D printing technology in-house on the latest high-resolution machines available.

The newly designed front plates are precisely CNC milled of 2.5mm Toray® premium high-grade graphite, the ultimate level of carbon fibers.

Improved X-Ventz™ System

Vented or non-vented tires? Depends on several factors and may varies comp by comp or by different wheel setups.

With the smartly improved integrated X-Ventz™ system of the Stonerockr™ V2 F6 Pro LCG Offset Wheels you can easily enable or disable tires ventilation by changing 3 of the bead screws and tires will vent even if the venting hole is fully covered by the bead ring.

Stainless steel hardware for enabling or disabling the X-Ventz™ function are included.

Extended Color Range For Both 1.9″ & 2.2″ Sizes

The Stonerockr™ V2 F6 Pro LCG Offset Wheels are available in both 1.9″ and 2.2″ sizes fitting all standard tires with an extended color range:

| Color | Size |

|---|---|

| Stonerockr™ Fluo Pink | 1.9"/2.2" |

| Flatgekko™ Fluo Green | 1.9"/2.2" |

| Yuuki™ Fluo Red | 1.9"/2.2" |

| Grind™ Fluo Blue | 1.9"/2.2" |

| Black | 1.9"/2.2" |

| Silver | 1.9"/2.2" |

Amazing 6-Size Offset For Perfect Track-Width

A 245mm track-width on Capra axles and hiding the portals into the wheels to avoid hanging up? With Stonerockr™ V2 F6 Pro LCG Offset Wheels, yessir.

Narrowest Track Width

| Axles | Hex Hub | Track Width |

|---|---|---|

| AR44 | 12mm | cca. 224mm |

| AR45 | 12mm | cca. 224mm |

| AR45P | 12mm | cca. 224mm |

| Enduro | 12mm | cca. 224mm |

| F10 Phoenix | 12mm | cca. 224mm |

| Capra | 6mm | cca. 245mm |

| TRX-4 | 6mm | N/A |

100% Legal To All Major Rulesets

The Stonerockr™ V2 Pro LCG Offset Wheels are 100% legal to all major competition rulesets such as SORRCA, WRCCA, ISRCC™, Linekillaz Compz™, C.I.S.E. and ASTS out of the box, no after-purchase modifications or hacking needed.

All-Made In EU

Each and every part of the Stonerockr™ V2 F6 Pro LCG Offset Wheel System has been personally designed by PROCRAWLER® founder Pierre Silva in Hungary/Europe. High-quality production is processed in-house on the latest state-of-the-art 3D printers using high-tech materials sourced from Europe and on hungarian CNC machines. So the Stonerockr™ V2 F6 Pro is crafted of the finest that Europe has.

Stonerockr™ V2 F6 Pro 1.9″

The most sophisticated ultralight 1.9″ LCG offset wheels in reach.

Stonerockr™ V2 F6 Pro 2.2″

The ultimate ultra light LCG offset wheels for big foot lovers.

Stonerockr™ V2 F6 Pro Spares

Pick all the spares you need for your V2 F6 Pro wheel setups.

Frequently Asked Questions

What purpose of use are Stonerockr™ V2 F6 Pro wheels for?

The Stonerockr™ V2 F6 Pro LCG Offset Wheels are designed for high-performance slow technical crawling as a primary purpose of use. These wheels are not recommended for bashing, rock racing or rock bouncing.

Stonerockr™ V2 F6 Pro LCG Offset Wheels are 100% SORRCA, WRCCA Performance Scale, ISRCC™, C.I.S.E. and ASTS legal and can be used on independent or cheater style competition events as well.

The Stonerockr™ V2 F6 Pro LCG Offset Wheels are not only for scaler or performance scale use they also can be used without the front rings for MOA (motor on axle) style comp crawlers.

Please get thoroughly informed about the comp event rules you plan to attend to avoid problems at tech-ins.

GET YOURS NOW!

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Parts ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Parts ➝

Why to choose ultra light LCG wheels?

Rotating weight is a bad weight. High rotating weight burdens the drive chain totally unnecessary and useless: the motor loses explosiveness and reaction time while the parts of the drive can easily break.

| Wheel Size | Net Weight |

|---|---|

| Stonerockr™ V2 F6 Pro 1.9" | 26g/wheel |

| Stonerockr™ V2 F6 Pro 2.2" | 30g/wheel |

The RTR (ready-to-run) weight of the Stonerockr™ V2 F6 Pro LCG Offset Wheels is 65% lower than other standard wheels. The result is a perfectly controlled, explosive and highly responsive performance-driven LCG crawler.

GET YOURS NOW!

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Parts ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Parts ➝

Which hex hub size to choose?

Choose the proper hex hub sizes to get the perfect track-width needed to achieve your goals on rocks. Different track-width for different comps? Pick all the hex hub sizes you need and change them easily in 60secs.

We summerized all the approximate track width with all hex hub sizes for all major axle types and their clones.

| Axles | Hex Hub | Track Width |

|---|---|---|

| AR44 / AR45 / AR45P / Enduro | 6mm | Not Recommended |

| AR44 / AR45 / AR45P / Enduro | 9mm | Not Recommended |

| AR44 / AR45 / AR45P / Enduro | 12mm | cca. 224mm |

| AR44 / AR45 / AR45P / Enduro | 15mm | cca. 230mm |

| AR44 / AR45 / AR45P / Enduro | 18mm | cca. 236mm |

| AR44 / AR45 / AR45P / Enduro | 22mm | cca. 244mm |

| Capra | 6mm | cca. 245mm |

| Capra | 9mm | cca. 251mm |

| Capra | 12mm | cca. 257mm |

| Capra | 15mm | cca. 263mm |

| Capra | 18mm | cca. 269mm |

| Capra | 22mm | cca. 277mm |

| TRX-4 | 6mm | N/A |

| TRX-4 | 9mm | N/A |

| TRX-4 | 12mm | N/A |

| TRX-4 | 15mm | N/A |

| TRX-4 | 18mm | N/A |

| TRX-4 | 22mm | N/A |

Sold in pair so price includes 2x chosen sized hex hubs and stainless steel hardware. If you need more hex hub sizes, you can add the optional hex hubs to the cart separately.

Please consider that one set includes 2pcs so you need to pick 2 sets (2x2pcs) to fully equip your rig.

GET YOURS NOW!

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Parts ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Parts ➝

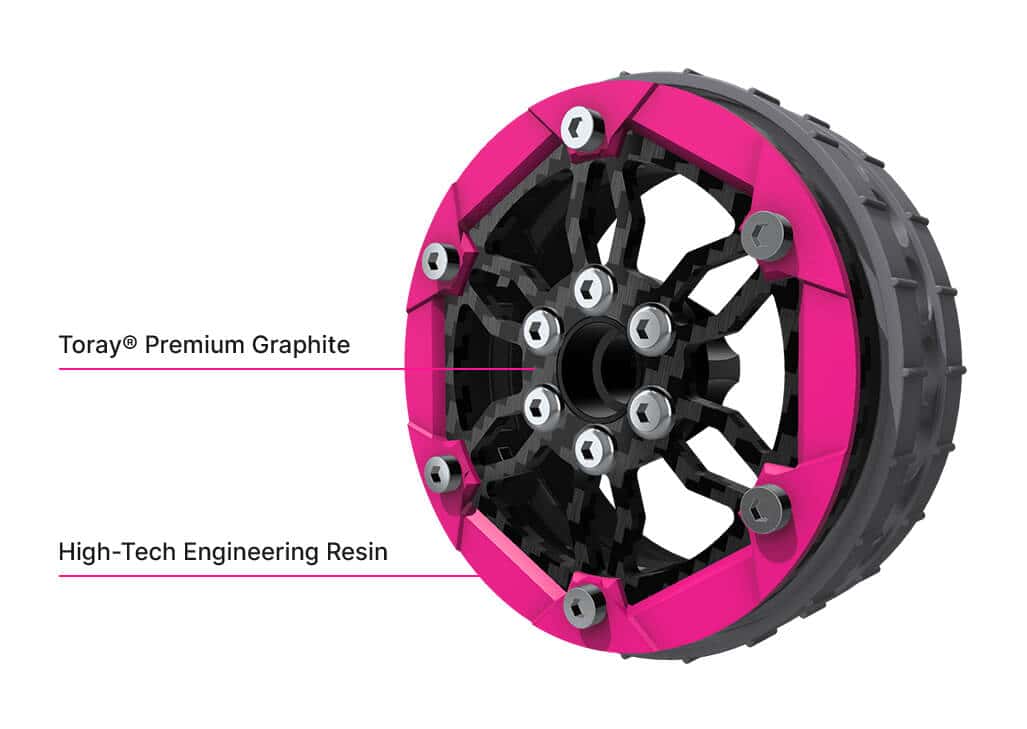

What materials and technologies do you use?

When engineering the details of the Stonerockr™ V2 F6 Pro LCG Offset Wheels we keep on using the latest technologies and high-tech materials.

Toray® Premium High-Grade Graphite

Toray’s M-series high modulus carbon fibers represent the highest modulus PAN-based carbon fibers available. PAN-based high modulus fibers are superior to pitch-based fibers due to tensile and compressive strengths that are often times more than twice that of a corresponding pitch-based fiber.

High-Tech Engineering Resin

Engineering resins refer to a class of high-performance, often specialized, photopolymer materials used in resin-based 3D printing technologies like stereolithography (SLA) and digital light processing (DLP). These resins are designed to meet specific engineering requirements, offering properties such as high strength, durability, heat resistance, and chemical resistance.

Engineering resins are formulated to provide superior mechanical properties, making them suitable for functional prototypes and end-use parts that require strength and durability. Engineering resins are engineered to be tough, meaning they can absorb energy and resist fracture, making them suitable for impact-resistant applications. These resins typically offer high resolution and fine detail, allowing for the production of intricate and precise parts.

GET YOURS NOW!

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Sets ➝

Stonerockr™ V2 F6 Pro 1.9″ LCG Offset Wheel Parts ➝

Stonerockr™ V2 F6 Pro 2.2″ LCG Offset Wheel Parts ➝